The University of Macau (UM) has achieved many results in scientific research over the years in areas such as environmental engineering, traditional Chinese medicine, advanced materials, microelectronic chips, and the internet of things for smart cities. With the right people in the right place at the right time, the university is steadily transferring these innovative results with great commercial prospects from the laboratory to the production line in order to turn them into hi-tech products via its system for research innovation and results transfer. This is in line with the university’s mission to benefit society through research.

Tapping Sewage Sludge as a Source of High-Value Products

A research team at UM has developed a system to recover high-value resources from sewage sludge produced by municipal sewage treatment plants. The system was introduced to the Macao public during the Science and Technology Week 2021 cum Exhibition of Achievements in Science and Technology Innovation, which was organised by the Science and Technology Development Fund of Macao (FDCT) and supported by the Ministry of Science and Technology. The system can extract industrial-grade sulfated polysaccharides from residual sludge of secondary clarifiers in sewage treatment plants. The extract can be broken down into useful substances such as industrial-grade sodium alginate, carrageenan, and potassium alginate. The team, which has received two Chinese patents for developing the system, has been in talks with several environmental engineering companies and venture capital firms about collaboration through UM’s Research Services and Knowledge Transfer Office (RSKTO).

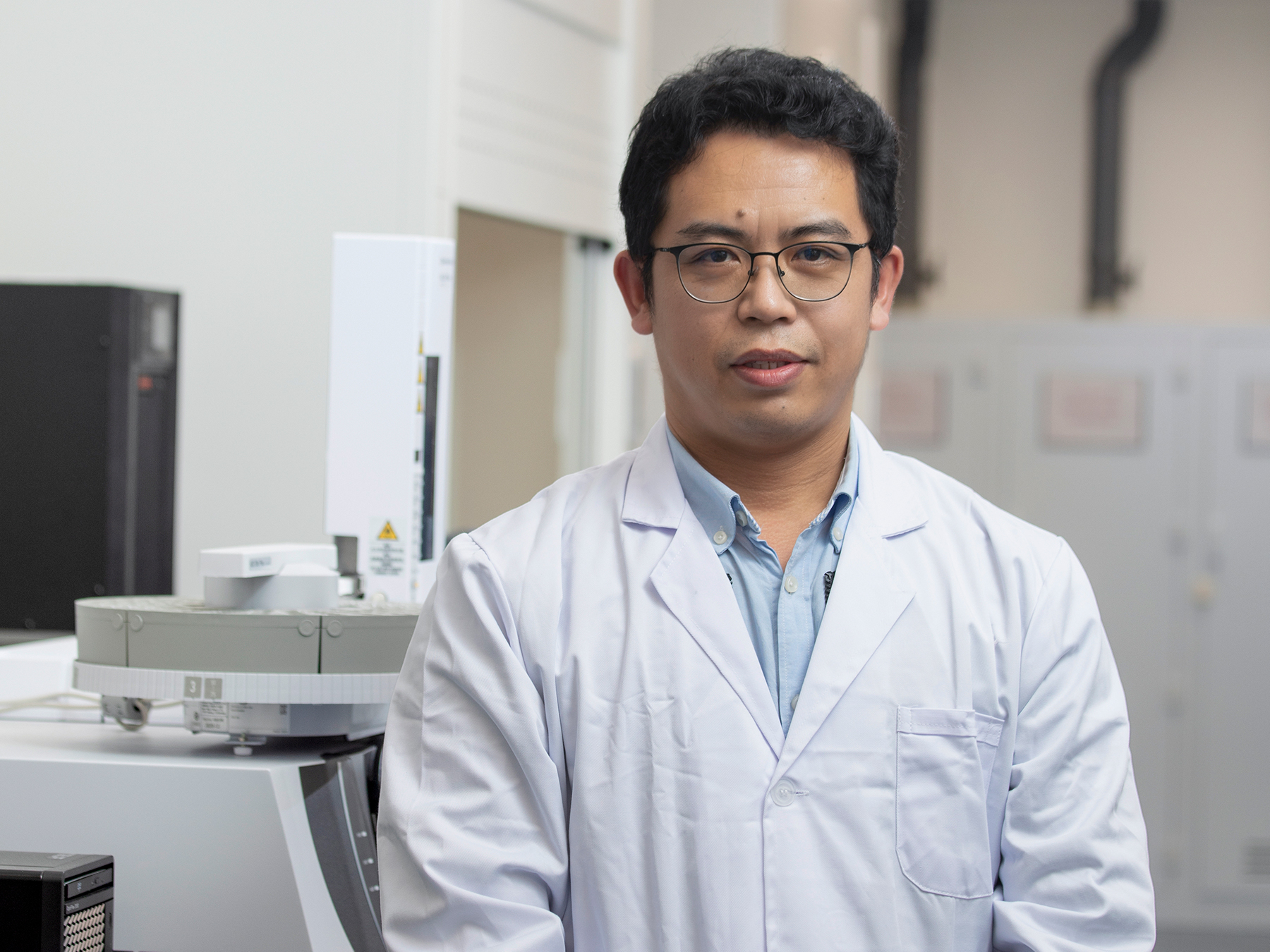

In terms of technical maturity, the system has reached level 6 of the Technology Readiness Level (TRL), and tests conducted by an industrial partner have shown that the polysaccharides extracted by the system not only meet the Chinese quality standards for industrial-grade products; they can also produce algae products with the same degree of purity as those available on the market. The global demand for industrial-grade sulfated polysaccharides is growing rapidly, reaching USD 15.43 billion in 2021 alone. This contrasts with an acute shortage of conventional medical-grade sulfated polysaccharides, which are difficult and time-consuming to produce. ‘Our system can be used at a wide range of urban sewage treatment plants. If the system treats 100 tons of sewage sludge per day, we can obtain about 1,300 tons of sulfated polysaccharides in a year,’ says Hao Tianwei, head of the research team for the project. He is also an assistant professor at the Centre for Regional Oceans (CRO) and the Department of Civil and Environmental Engineering. ‘If we sell the polysaccharides at 60 per cent of the current market price for industrial-grade products, our annual revenue could exceed RMB 10.4 million.’

Through the CRO, Prof Hao’s team has continuously refined the process of extracting sulfated polysaccharides from sewage sludge in order to obtain medical-grade products. He points out that since 1987, when scientists discovered that sulfated polysaccharides could inhibit HIV, more potential functions of the polysaccharides have been revealed, such as the treatment of blood clots, immune inflammation, and tumours. ‘We have confirmed that sulfated polysaccharides extracted from sewage sludge have anti-tumour and anticoagulant effects,’ says Prof Hao.

‘Tons of sewage sludge are produced every day when treating domestic sewage and industrial wastewater. Instead of burning it, why not use it and turn the waste into high-value products?’ says Prof Hao, who also admits that by-products of sewage sludge are not yet widely accepted by the public due to prejudice. ‘As of today, only India allows the use of sulfated polysaccharides from sewage sludge for medical purposes. We need to make more efforts to promote these research results in order to change people’s minds.’

Traditional Chinese Medicine-based Innovative Products

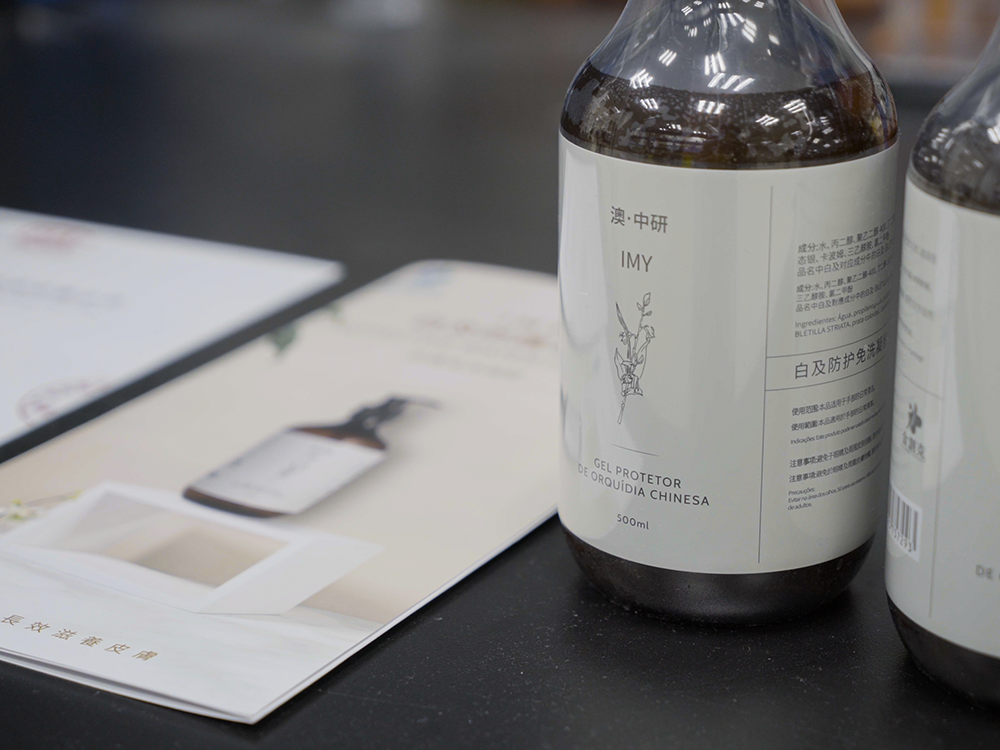

Currently, three projects based on polysaccharides derived from Chinese medicinal herbs are being developed at UM, namely a dressing for diabetic foot ulcers, a glucomannan coating for bone tissue regeneration, and an alcohol-free and rinse-free antibacterial moisturising hand gel. The research results are being transferred at Genetrump Co, Ltd, a start-up company incubated at UM and partly owned by UMTec Limited. Some of the research results are close to the stage of clinical trials, while some others have been launched on the market. These achievements are the results of a research team at UM’s State Key Laboratory of Quality Research in Chinese Medicine after a decade of hard work. In 2017, the team founded Genetrump, which moved into UM’s Centre for Innovation and Entrepreneurship in the same year and received the first round of seed investment from UMTec Limited.

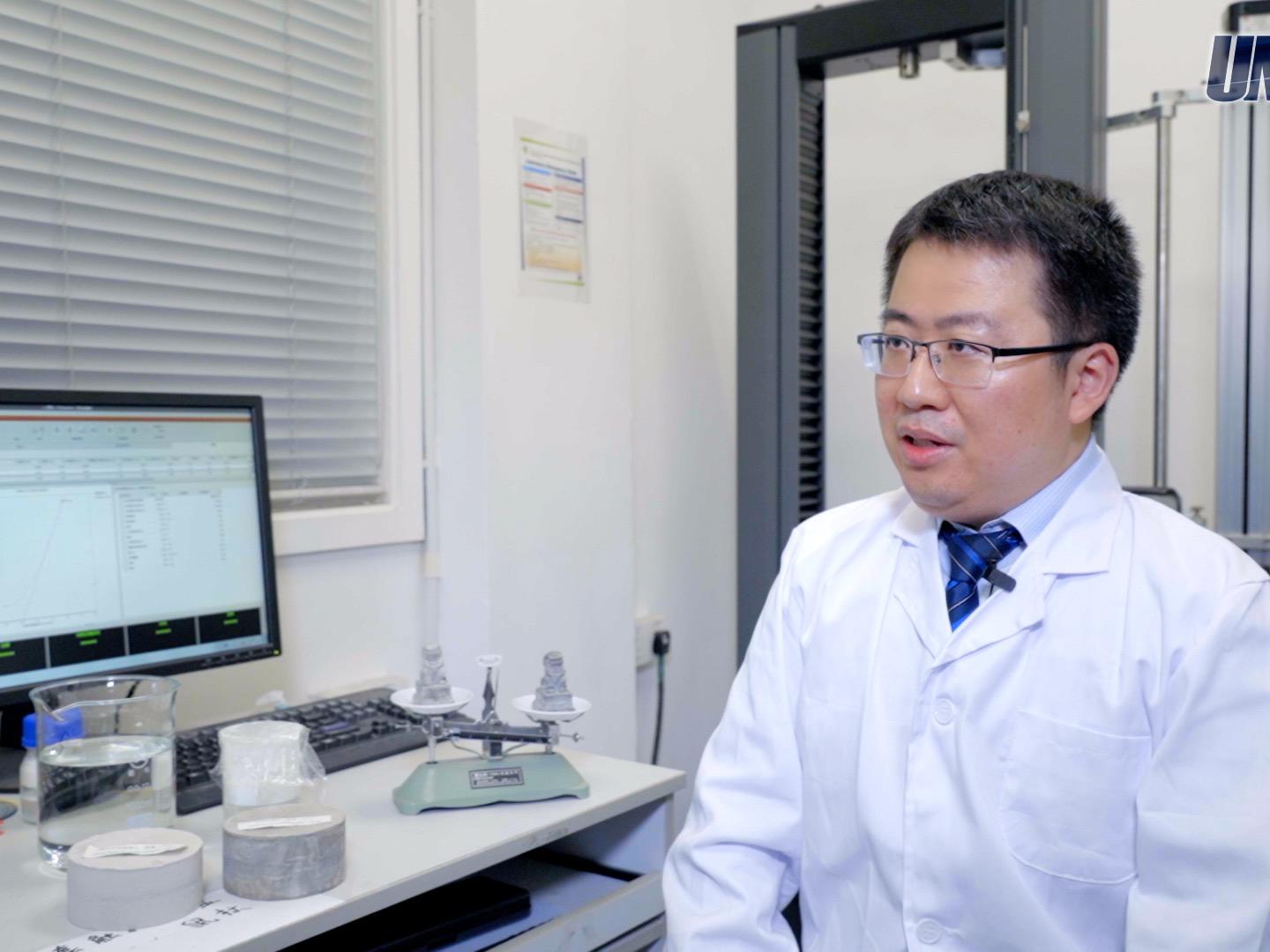

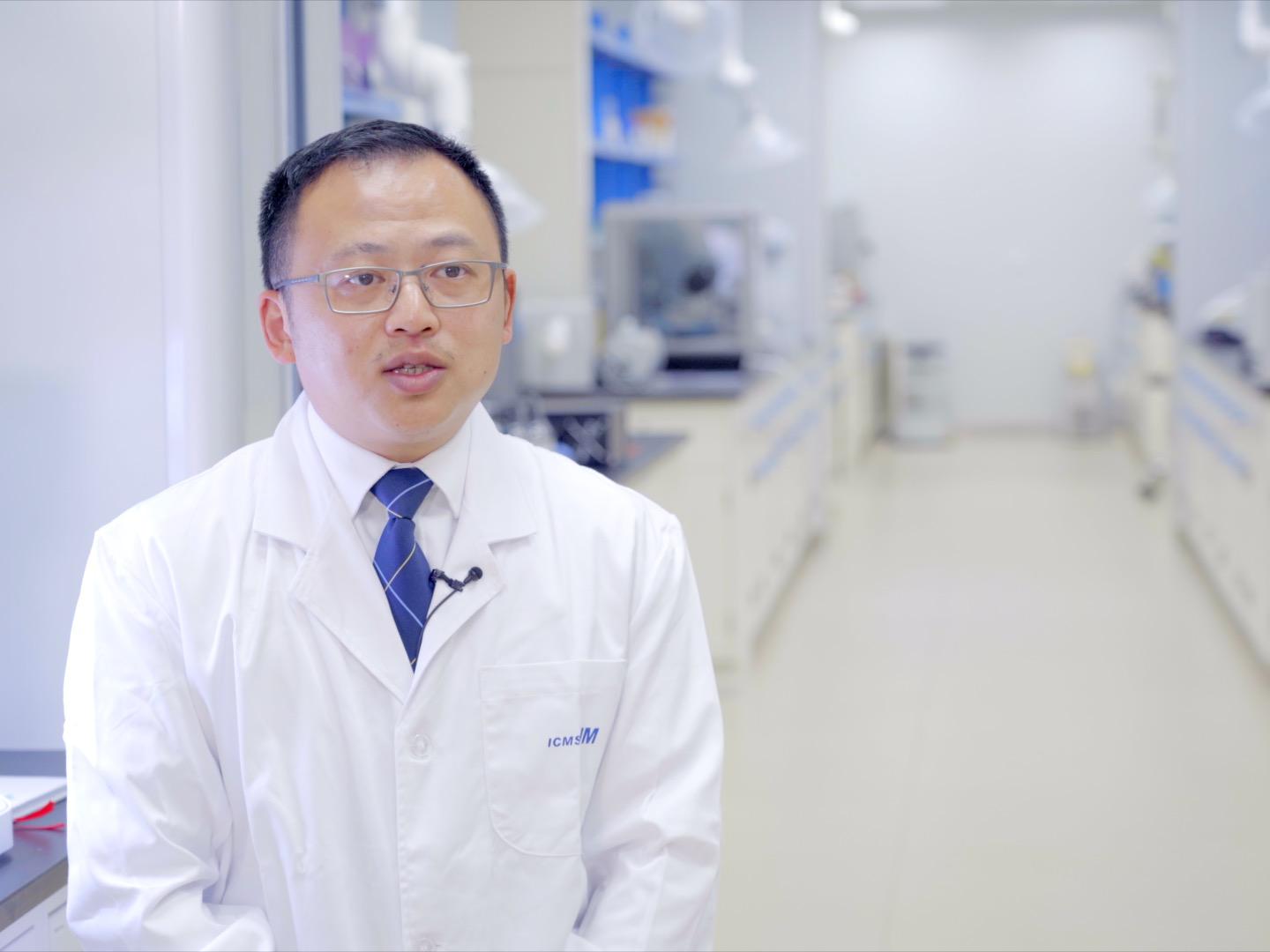

Technique and quality control are key in the process of transforming research results into finished products. ‘Few medical products are available in the market for treating diabetic ulcers. Our dressing is developed from a natural compound derived from the plant Du Zhong (Eucommia ulmoides) and is effective in improving blood flow to affected areas in laboratory mice. In cases where our medicine is applicable, the dressing has the potential to significantly reduce the need for amputations in diabetic patients,’ says Wang Chunming, associate professor in UM’s Institute of Chinese Medical Sciences and head of the research team for the three projects. Prof Wang is also a recipient of the National Science Fund for Outstanding Young Scholars from the National Natural Science Foundation of China, and he is a ‘Qi-Huang’ Young Scholar recognised by the State Administration of Traditional Chinese Medicine. ‘Many people develop osteoporosis as they age. Currently, we can use artificial implants such as titanium implants to strengthen the bones. To improve the integration of the implants and the bone in patients, we have developed a glucomannan coating, in the hope of giving patients the same quality of life as before. Because of the pandemic, we have also developed an antibacterial hand gel that is not only alcohol-free but also skin-friendly. According to tests conducted by a third-party institute, the gel can kill 99 per cent of bacteria and will not make the skin dry after use,’ says Prof Wang.

The three research projects are supported by the FDCT and are among the results of the years of development of the Chinese medicine industry in Guangdong and Macao. The projects are also real-life examples of the development of the health industry in Macao with Chinese medicine R&D and production as the entry point. Prof Wang’s team is seizing the opportunity brought by the Guangdong-Macao In-Depth Cooperation Zone in Hengqin during its development into a world-class centre for Chinese medicine production and innovation. The team is also taking advantage of the industry-academia platforms at the Zhuhai UM Science & Technology Research Institute (ZUMRI) and the Macau Institute for Translational Medicine and Innovation to commercialise its research results. The team will begin clinical trials with hospitals in order to launch the products on the market as soon as possible. According to Prof Wang, his team has procured industrial equipment for these three products and will soon set up production lines. ‘We are also confident that these products will help to reduce health problems associated with the ageing population.’ says Prof Wang.

Green Building Materials and Related Construction Technique Applied in Zhuhai

A construction technique using a special formula of cast-in-place nano-foam concrete developed by UM was tested in a pilot project in September 2021 in Henan province and was proven to be effective. The technique was subsequently applied in March 2022 in a project of China Construction Engineering (Macau) Company Limited in the Zhuhai National Hi-tech Industrial Development Zone, during which 5,000 cubic metres of nano-foam concrete was used to backfill a trench between the perimeter of the main structure underground and the maintenance pit. Compared to available materials on the market, UM’s cast-in-place concrete solution uses 30 per cent less cement, significantly reducing material cost and carbon emissions.

This specialised concrete has been launched on the market by a building materials company in Zhongshan founded by UM professors and students with the support of ZUMRI. The company has also set up production lines in cities such as Nantong in Jiangsu province and Taiyuan in Shanxi province to produce nano-foam concrete boards, another type of green building material developed by UM. According to Sun Guoxing, associate professor in the Institute of Applied Physics and Materials Engineering and head of the research team for the project, construction techniques and products using nano-foam concrete have matured and have entered the stage of market expansion. ‘Innovation in materials is the basis for innovation in industrial development, especially in the construction sector. In the process of exploring opportunities to commercialise our research results, we have found that material innovation together with technical innovation can drive the mass production of new materials and the development of industries.’ says Prof Sun.

According to a report on the energy consumption of buildings in China released in 2020, the construction sector accounted for 46.5 per cent of the total energy consumption in the country in 2018, and cement production was a major source of carbon emissions. The lightweight and high-strength nano-foam concrete developed by Prof Sun’s team can significantly reduce cement consumption, improve the insulation capacity of buildings, and reduce energy consumption and carbon emissions during the heating and cooling processes in buildings. ‘Our nano-foam concrete is also suitable for cast-in-place projects such as roof insulation, floor damping, aerial structures (such as sky pools), road construction, and the backfilling of large mines. Using our material, we can reduce cement consumption by 30 per cent to greatly cut the cost of materials. The capacity for constant thermal insulation is also increased by 25 per cent,’ says Prof Sun.

‘With the data provided by China Construction Engineering (Macau) Company Limited and research platforms of the ZUMRI, we will continue to improve our cast-in-place concrete technique and investigate its downstream applications, so as to promote the commercialisation of our research results and the industry of green building materials in China,’ adds Prof Sun.

Chip Research Results Transfer in Hengqin Entrepreneurship Valley

Taking advantage of the research capacity of the State Key Laboratory of Analog and Mixed-Signal VLSI (SKL-AMSV), UM continues to push the boundaries in advanced chip research. Through its robust system for research innovation and results transfer, the university aims to accelerate the commercialisation of its microelectronics research results and establish a brand identity for microchips developed in Macao.

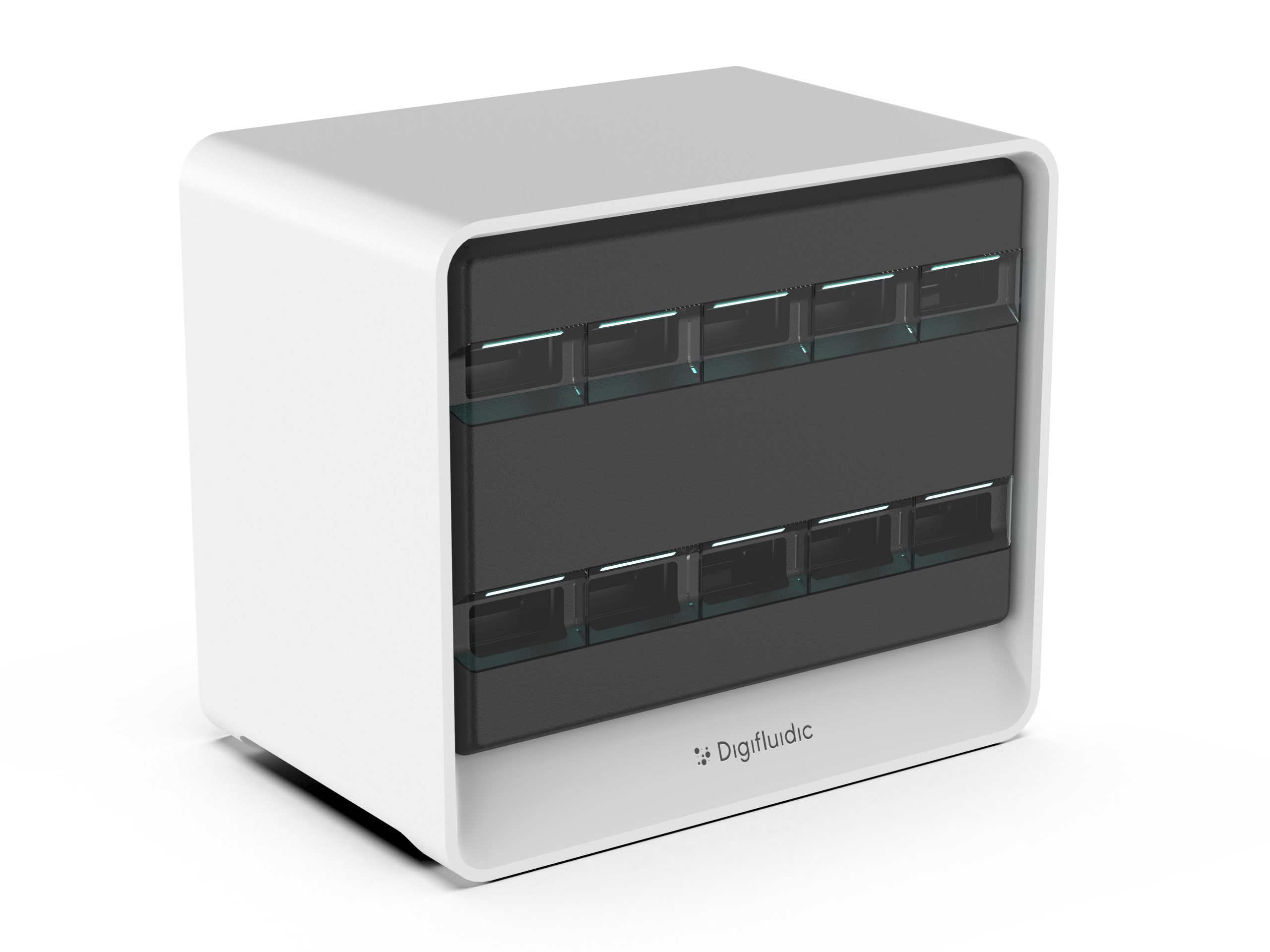

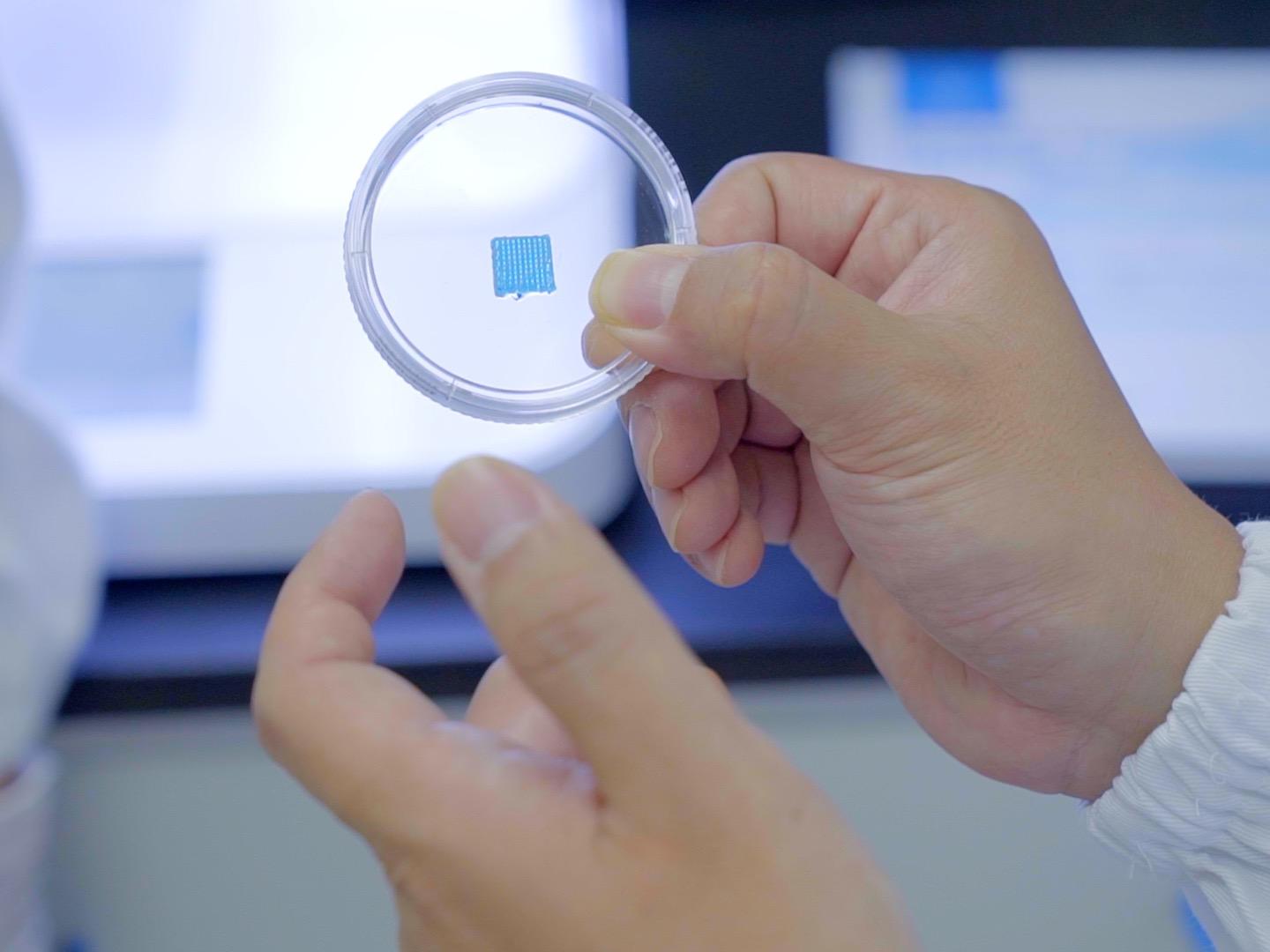

Among these research results is VHunter, a nucleic acid detection kit based on digital microfluidic technologies developed at UM. The research team for this project turned its initial lab findings into a business project through incubation at UMTec Limited. In 2018, the team members established Digifluidic Biotech Ltd and received an initial round of investment from UMTec. With ZUMRI’s support, the company was able to commercialise the research results in the Hengqin-Macao Youth Entrepreneurship Valley and the finished product has been launched on the market in mainland China.

Prof Mak Pui In, head of the research team for the project, who is also interim director of the SKL-AMSV and deputy director of UM’s Institute of Microelectronics (IME), says that the university provided tremendous support for the team to market VHunter. ‘Not only did UM license the patented chip technology to the new start-up, but the university also took an equity stake in the company. This is also the first time that UM has taken an equity stake in a company founded by its graduates,’ says Prof Mak, who adds that Digifluidic plans to leverage the strengths of Macao and its partners to bring VHunter to the Southeast Asian market.

VHunter can be widely used in infectious disease prevention and control as it can rapidly and accurately detect pathogens of diseases such as respiratory diseases (including novel coronavirus and influenza A virus), cervical cancer, sexually transmitted diseases, and drug-resistant tuberculosis. The detection kit can also generate real-time reports when connected to a computer. In addition to medical diagnostics, VHunter is also suitable for measuring health indicators, examining animals and plants with diseases, and conducting food safety tests. The detection kit has been purchased and used by various entities, including the Zhuhai Center for Disease Control and Prevention, the Gongbei Customs, and the Doumen Aquatic Products Testing Center. It has also received the CE marking, which affirms the product’s conformity with EU standards. The team is now in the process of registering VHunter as a medical device in mainland China.

Dynamic Wireless Charging System Attracts Industry Attention

With the help of the RSKTO, a dynamic wireless charging system developed at UM made its debut at the Seventh Macau Industrial Products Show in 2020 and immediately attracted industry attention. In August 2021, the university signed an agreement with the Macao Water Supply Company Ltd. Based on this agreement, UM will provide wireless charging services for autonomous boats in local reservoirs, which will reduce labour costs by eliminating the manual operation of replacing batteries and using plug-in wired charging for the boats. This technology can also be applied to smart warehouses, where a dynamic wireless charging system can be installed on the ground to power warehouse robots around the clock, thus reducing the cost of manpower. Moreover, as the Macao Special Administrative Region government has been active in popularising electric vehicles, this technology can help to solve a dilemma facing the charging of these motorbikes — the diversity of charger types for different makes or models, as well as the high cost and safety hazards of the existing battery replacement cabinets in car parks. Formed by UM postgraduates from Macao, the research team for this project has founded a local company named Smarmac Technology Company Limited, which is specialised in designing and developing wireless charging systems and power electronics systems. The team hopes to commercialise this technology and apply it in different scenarios in Macao and other parts of the Greater Bay Area to contribute to the moderate economic diversification of Macao.

There are currently around 320,000 warehouses in mainland China, but less than 20,000 of them are considered smart warehouses. Lam Chi Seng, head of the research team for the project, who is also an associate professor at the SKL-AMSV and the IME, says that the market potential for this technology is huge, adding that the dynamic wireless charging technology developed by his team can meet the needs of the smart warehouse market. ‘The greatest strength of our system is its high charging efficiency of up to 94 per cent, which is better than similar wireless charging products on the market. Even with a 20 per cent misalignment from the charging position, the high charging efficiency is still guaranteed.’ says Prof Lam.

Macao has been striving to build a world-class smart city in recent years, with the goal of providing more high-quality services for its residents through smart basic infrastructures. Smart transport is one of the initiatives. The first step towards this development is to fully automate electric vehicle charging. ‘We can develop wireless charging receiver coil and circuit transmission pads for different makes or models of electric vehicles to achieve the most efficient wireless charging. When electric vehicles pass through the road paved with a wireless charging transmitter coil, they can be charged immediately.’ says Prof Lam.

The construction of a smart city is not completed without implementing efficient, convenient, and user-friendly power supplies. Prof Lam hopes that the wireless transmitter coils will be installed in front of traffic lights or zebra crossings to enable wireless charging services for electric vehicles whenever they pass by, so that they can travel further.

Source: UMagazine Issue 25

Related articles:

1. UM Collaborates with Enterprises to Promote Research Results Transfer

2. Accelerating Research Results Transfer through Various Platforms for Industry-Academia Collaboration

3. Promoting the Transfer of Innovative Medical Research Results in Macao

Chip technologies developed at UM are being commercialised in the Hengqin-Macao Youth Entrepreneurship Valley

Prof Hao Tianwei

A system to recover resources from sewage sludge produced by municipal sewage treatment plants

UM’s construction technique using nano-foam concrete is applied in the Zhuhai National Hi-tech Industrial Development Zone

Prof Sun Guoxing

Prof Mak Pui In

VHunter, a nucleic acid detection kit

Prof Wang Chunming

A dressing for diabetic foot ulcers

A rinse-free moisturising hand sanitiser gel

The dynamic wireless charging system reaches a charging efficiency of up to 94 per cent

Prof Lam Chi Seng